The American Association of State Highway and Transportation Officials (AASHTO) just recently published an updated 2016 edition of the Manual for Assessing Safety Hardware (MASH) document. [1, 2] Along with this, the Federal Highway Administration (FHWA) and AASHTO developed a revised joint implementation agreement which establishes dates for discontinuing the use of safety hardware that has met earlier crash testing criteria for new installations and full replacements on the National Highway System (NHS). Although some barrier testing was performed during the development of the updated criteria, many barrier systems and other roadside safety features had yet to be evaluated under the proposed guidelines. Therefore, evaluation of the remaining widely used roadside safety features using the safety-performance evaluation guidelines included in MASH was needed.

As we approach MASH implementation agreement sunset dates for National Cooperative Highway Research Program (NCHRP) Report 350 [3] devices many entities, individual state DOT’s, Pooled Funds, and private industry, will be crash testing highway safety devices to MASH standards. The objective of the project is to support the Roadside safety Pooled Fund participant DOTs during this MASH implementation era. Support will include:

The 2016 MASH edition is the latest in a series of documents that provided guidance on testing and evaluation of roadside safety features. The original MASH document was published in 2009 and represents a comprehensive update to crash test and evaluation procedures to reflect changes in the vehicle fleet, operating conditions, and roadside safety knowledge and technology. The MASH documents supersede NCHRP Report 350 standards.

The AASHTO Technical Committee on Roadside Safety (TCRS) is proposing a new MASH implementation plan that has compliance dates for installing MASH hardware that differ by hardware category. After December 31st 2019, all roadside safety devices must have been successfully tested and evaluated according to the 2016 MASH standard edition. The FHWA will no longer issue eligibility letters for highway safety hardware that has not been successfully crash tested according to the 2016 MASH edition evaluation criteria.

MASH was developed to incorporate significant changes and additions to procedures for safety-performance evaluation, and updates reflecting the changing character of the highway network and the vehicles using it. For example, MASH increased the weight of the pickup truck design test vehicle from 4409 lb to 5000 lb, changed the body style from a ¾-ton, standard cab to a ½-ton, 4-door, and imposes a minimum height for the vertical center of gravity (CG) of 28 inches. The increase in vehicle mass represents an increase in impact severity of approximately 13 percent for pickup truck design test vehicle with respect to the impact conditions of NCHRP Report 350. The increased impact severity may, therefore, result in increased impact forces and larger lateral barrier deflections compared to NCHRP Report 350.

The impact conditions for the small car test have also changed. The weight of the small passenger design test vehicle increased from 1800 lb to 2420 lb, and impact angle increased from 20 degrees to 25 degrees. These changes represent an increase in impact severity of 206 percent for Test 3-10 with the small car design test vehicle with respect to the impact conditions of NCHRP Report 350. This increase in impact severity might result in increased vehicle deformation and could possibly aggravate vehicle stability.

MASH defines six test levels for longitudinal barriers. Each test level places an increasing level of demand on the structural capacity of a barrier system. At a minimum, all barriers on high-speed roadways on the NHS are required to meet Test Level 3 (TL-3) requirements. The structural adequacy test for this test level consists of a 5000-lb pickup truck (denoted 2270P) impacting a barrier at 62 mph and 25 degrees. The severity test consists of a 2420-lb passenger car (denoted 1100C) impacting the barrier at 62 mph and 25 degrees.

Most state departments of transportation require that their bridge railings and/or median barriers meet Test Level 4 (TL-4), which requires accommodation of a 24,240-lb single unit truck (denoted 10000S) impacting the barrier at 56 mph and 15 degrees. Higher containment barriers are sometimes used when conditions such as a high percentage of truck traffic or the nature of a hazard underlying a bridge so warrant. Higher test levels (e.g., TL-5 and TL-6) include evaluation with 36,000-lb tractor-van trailers and tractor-tank trailers. Such barriers are necessarily taller, stronger, and more expensive to construct. Under TxDOT Research Project 9-1002 ‟Roadside Safety Device Crash Testing Program,” TTI researchers investigated the minimum height and lateral design load for MASH TL-4 bridge rails. Under MASH, the severity of TL-4 impacts increased substantially. Consequently, 32 inch tall barriers that met TL-4 requirements under NCHRP Report 350 do not satisfy MASH. The minimum rail height for MASH TL-4 barriers was determined to be 36 inches, and the lateral design load was determined to be 80 kips. Since the impact speed for the single unit truck will likely increase for the high-speed applications considered under the current proposal, both of these values will also increase.

The passenger vehicle impact speed recommended in MASH (i.e., 62 mph) was derived from analyses of reconstructed crash data collected on roads with design speeds up to 70 mph. It is reasonable to expect that impact speeds will increase for roadways with a speed limit of 75 mph and higher. The increased speeds will place more demand on roadside safety features. For economic reasons, many existing roadside safety features are optimized for the current design impact conditions. Consequently, they have little or no factor of safety for accommodating more severe impacts. Thus, designers might not have safety devices appropriate for use on facilities with high design speeds.

MASH also adopted more quantitative and stringent evaluation criteria for occupant compartment deformation than NCHRP Report 350. Just as an example, NCHRP Report 350 established a 6-inch threshold for occupant compartment deformation or intrusion. MASH, on the contrary, limited the extent of roof crush to no more than 3.9 inches. In addition, MASH requires that the vehicle windshield would not sustain a deformation greater than 3 inches and would not have holes or tears in safety lining as a result of the test impact. Although these evaluation criteria are applicable to all roadside safety devices testing, they are most relevant for sign supports design and testing. In addition, little evaluation of sign supports has been performed with larger vehicles such as the pickup. Systems that have been demonstrated to be crashworthy for passenger cars may not be geometrically compatible with pickup trucks. An increase in impact severity might result in increased vehicle deformation and could possibly result in failure of meeting the latest MASH evaluation criteria.

The objectives of this project are to assist the DOTs with coordination of information and testing activities related to MASH implementation program, and prioritize roadside devices based on DOTs preferences.

The DOTs will have support for developing databases with information regarding devices already tested according the MASH, as well as a wish list with devices that Stated would like to be tested according to MASH. DOTs will also have support with MASH testing prioritization, FHWA eligibility letters requests, and other small tasks in support of the pooled fund program.

The researchers will develop and maintain a database of MASH tested devices with granted FHWA eligibility letters, MASH tested devices without FHWA eligibility letter, and DOT needs for MASH testing. Within this project, support will be provided to help with the identification of devices for testing prioritization for, as well as eligibility letter request development.

The researcher will offer their experience, knowledge and capabilities to fulfill specific requests which might arise from the participant DOTs to support roadside safety devices MASH implementation.

The researchers will coordinate information and testing activities related to MASH implementation program. Under this effort, researchers will be actively reaching out to DOTs, FHWA, and testing Agencies to retrieve information for maintain a database of MASH tested devices, with and without granted FHWA eligibility letters.

A MASH tested hardware database has already been developed through a previous effort supported by the Roadside Safety Pooled Fund (Figure 1). This database, however, is considered a live document, since it constantly needs updates based on the most recently tested devices and FHWA approved systems. Maintenance of this MASH database includes various benefits such as providing State DOT’s the opportunity to better plan their tests, reduce the risk of duplicate efforts and provide an opportunity for collaboration between states on mutually beneficial projects. The Roadside Safety Pooled Fund Program Website was identified as a strategic location for storing this information and making it readily available to user’s request.

Figure 1. MASH Tested Hardware Database.

The researchers will continue working with State DOTs representatives to identify the current and future DOTs needs and preferences for MASH testing devices. These databases contain basic information of device characteristics and, if applicable, their test specifics, based on the category they belong to.

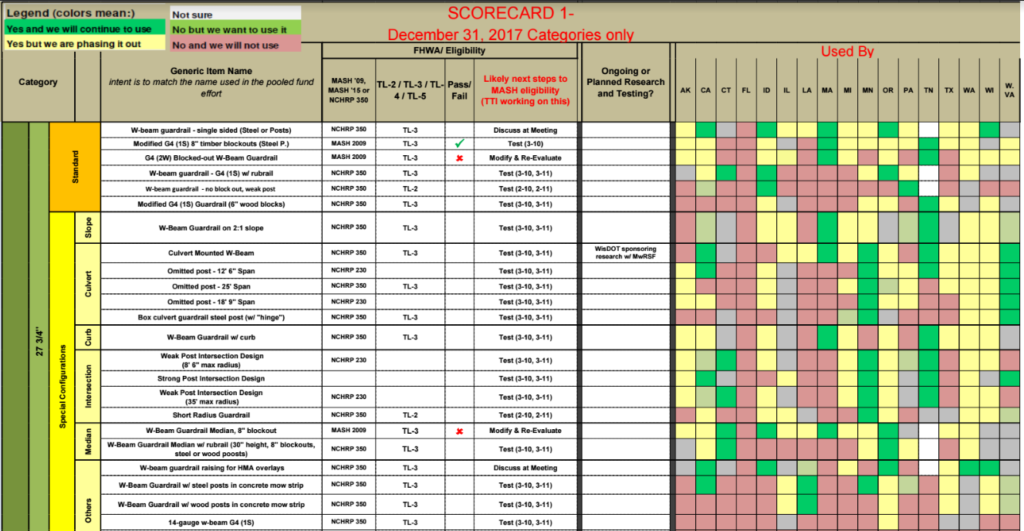

The researchers will collect information to develop Scorecards for the roadside Safety Pooled Fund participant DOTs. Each Scorecard refers to one or multiple roadside safety categories based on the MASH Implementation Plan deadlines required by AAHSTO /FHWA.

Within each Scorecard, a list is developed of known available roadside safety systems belonging to a specific category. The systems are further subcategorized when possible for easier identification. Each Scorecard also contains additional information, such as

Figure 2. Example of Scorecard.

Figure 2. Example of Scorecard.

Each pooled fund participant DOT will then review and “score” each entry based on their interest in adopting and maintaining that device through their MASH Implementation State Plan. The devices will then be prioritized by category based on the total score assigned by the DOTs’ feedback. Completion of this Task is expected to be prior to the Annual Roadside Safety Pooled Fund Meeting, which usually occurs during the month of October.

Throughout the research effort, the researchers will coordinate with other known research initiatives to share information and avoid duplication of efforts. The researchers will communicate regularly with DOTs and FHWA to verify if and when other similar research efforts develop, so that common objectives can be integrated among studies.

The researchers will communicate directly with the other testing Agencies in order to identify engineering evaluation, computer simulations, testing, or any other efforts undertaken with the objective to evaluate roadside devices.

Within this project, support will be provided to the pooled fund DOTs to help with FHWA eligibility letters request development.

| TTI Research Supervisor: Chiara Silvestri Dobrovolny, Ph.D. Associate Research Scientist Texas A&M Transportation Institute TAMU 3135 College Station, Texas 77843-3135 (979) 845-8971 [email protected] |

Pooled Fund Technical Representative: Jeffery K. Petterson, P.E. Design Policy & Strategic Analysis Estimating Manager Roadside Safety Engineer Washington State Department of Transportation (WsDOT) P.O. Box 47329 Olympia, WA 98504-7246 (360) 705-7278 [email protected] |

2017-04-13