| TTI Research Supervisor: Nauman M. Sheikh, P.E. Research Engineer Texas A&M Transportation Institute Texas A&M University System TAMU 3135, College Station, Texas, 77843-3135 (979) 317-2695 [email protected] | Pooled Fund Technical Representative: Tim Moeckel, P.E. Policy Support Engineer WSDOT Development Division Washington State Dept. of Transportation (360) 704-6377 [email protected] |

WSDOT needs to protect pedestrians by installing fall-protection rails on fish-passage concrete

culverts that are sometimes installed under roadways. To protect the motoring public on these

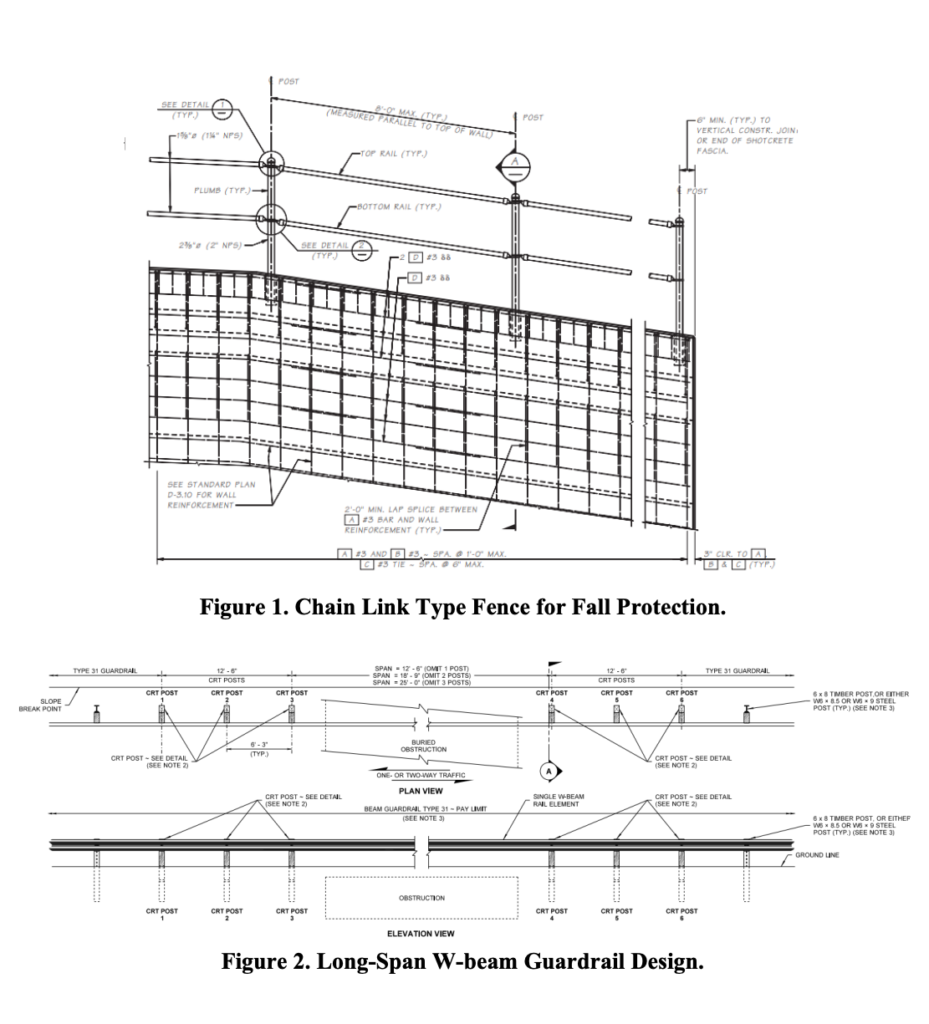

roads, there is also a need to install roadside guardrails. A long-span W-beam guardrail design

with a 25-ft wide long spacing between posts can be installed over many of the concrete culverts.

This W-beam long-span guardrail has been crash tested to Test Level 3 (TL-3) of American

Association of State Highway and Transportation Official’s (AASHTO) Manual for Assessing

Safety Hardware (MASH). (1,2) However, it was not crash tested when a fall-protection rail is

installed within the deflection zone of the guardrail, which is up to 7.69 ft.

There is a possibility that an errant vehicle that impacts the long-span guardrail might have a

secondary impact with the fall protection rail. This secondary impact can be significant and is

likely dependent on the lateral offset of the fall protection rail from the back of the long-span

guardrail, as well as the design of the fall protection rail. There is a need to evaluate this longspan guardrail and fall-protection device combination under MASH TL-3 impact conditions to

ensure that the impacting vehicle will be safely contained and redirected.

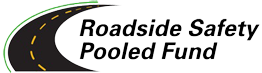

WSDOT is interested in evaluating use of its fall protection rail that is comprised of poles and

cross-members of a typical industrial-grade chain-link fence (see Figure 1). The long-span Wguardrail guardrail design has a 25 ft. span of guardrail without any posts as shown in Figure 2

(WSDOT Standard Plan C-20.40-07). This design is based on a system crash tested by Midwest

Roadside Safety Facility (MwRSF) in which the guardrail had a maximum dynamic deflection of

7.69 ft. when crash tested with a 4,991-lb pickup truck under the impact conditions of MASH. (2)

The project objective is to evaluate the performance of the long-span W-beam guardrail system

for MASH TL-3 compliance when a chain link fence type fall protection device is installed

behind it. The project shall first evaluate the system through finite element (FE) modeling and

impact simulations. This simulations analysis shall be used to determine the minimum lateral

offset the fall protection rail at which the design has a reasonable chance of passing MASH

testing. The design shall be further evaluated through full-scale crash testing using the MASH

TL-3 testing and evaluation criteria for longitudinal barriers.

Successful design and evaluation of the long-span W-beam guardrail with the fall protection

device will allow WSDOT to achieve MASH compliance of the guardrail and provide safe

passage for the pedestrians and the motorists over the fish passages. The project may determine

that a certain offset is needed behind the long-span guardrail for acceptable performance; or it

may suggest some design changes to improve performance. It is also possible that the project

determines that the existing fall protection device does not allow safe functioning of the guardrail.

In this case, WSDOT will know the extent of the problem and will be able to determine a path

forward for resolving the problem through further research.

The TTI research team will provide composite video and photographic documentation of the crash test and a final report documenting the research and testing performed. The TTI research team will provide standard drawings of the transition system evaluated through full-scale crash testing. The TTI research team will include the guidelines, recommendations, and engineering opinion for MASH compliance for other less critical concrete F-Shape barrier heights in the final report

The TTI research team proposes the work plan tasks below to accomplish the project objectives.

Task 1 – Simulation Analysis

The TTI research team will develop a full scale FE model of the long-span W-beam guardrail

with the chain link type fence. The TTI research team will model all critical parts of the system

using elastic-plastic material models, or wood or soil models as appropriate. Regions or parts

that are insignificant to the simulation analyses, or are not expected to undergo deformation or

failure, will be modeled using rigid or elastic material models as appropriate. The FE model will

be developed for LS-DYNA, which is a commercial general purpose FE solver commonly used

for crash analysis.

After development of the FE models, the TTI research team will perform two impact simulations

as follows.

Both simulations will involve a vehicle impacting the guardrail at an impact speed of 62 mph at

an impact angle of 25 degrees. Simulation of Test 3-11 will involve impacting with a 5,000-lb

pickup truck, whereas the simulation of Test 3-10 will involve impacting with a 2,425-lb small

passenger car. In both simulations, the TTI research team will use full-scale models of the test

vehicles that are available in the public domain. These models were developed by Center for

Collision Safety and Analyses through funding from NHTSA and FHWA. These models have been modified from their public domain release versions by TTI researchers to improve their

accuracy and robustness over the course of many projects involving simulation and testing.

The TTI research team will initially perform the simulations with the fall protection device

placed at no lateral offset behind the posts of the long-span W-beam guardrail. If the simulations

determine that some lateral offset is needed for successful performance of the guardrail, the TTI

research team will increase the offset in consultation with WSDOT and perform additional

simulations.

As part of the simulation analyses, the TTI research team will perform additional impact

simulations to determine the critical impact points of the system for full-scale crash testing.

Based on the results of the simulations, the TTI research team will make recommendations for

full-scale crash testing.

Task 2 – Test Installation Construction

The TTI research team will construct a full-scale test installation of the long-span W-beam

guardrail with the fall protection device. Preliminary sketches of the construction site and the

guardrail and fence system used for planning and budgeting purposes are shown in Figure 4. A

vertical reinforced concrete wall that will be cast in place over a buried moment slab foundation

will be used as a surrogate culvert structure. The long span guardrail will be installed in front of

the wall with an offset determined in Task 1. The chain link type fence will be installed on top of

the vertical wall.

This task includes preparing full system drawings of the test installation that are suitable for

soliciting construction bids. It also includes managing the third-party vendor during the

construction of the test installation. This task also includes the cost of demolishing the test

installation after the testing and restoring the test site to original conditions.

In the absence of a final design, obtaining a firm construction price is not straightforward without

being overly conservative. Furthermore, cost of various parts can change between the time of the

proposal and the time of the crash testing. The TTI research team have determined the total

estimate of Task 2 based on a construction cost of $58,590 (inclusive of TTI’s overhead). If the

construction bids at the time of the performance of Task 2 are higher than the proposed estimate

(after including TTI’s overhead), additional funds will be needed for this project.

Task 3 – Testing and Reporting

The TTI research team will perform MASH Test 3-11 (pickup truck) and Test 3-10 (small car)

with the long-span W-beam guardrail system with the fall protection device. The TTI research

team will conduct the full-scale crash tests at its International Standards Organization (ISO)

17025-accredited laboratory.

The TTI research team will procure and prepare the test vehicles for crash testing by installing

the instrumentation necessary to record dynamic testing data, such as vehicle acceleration and

rotation, and the instrumentation necessary to guide the vehicle into the test installation at high

speeds and stop it after the impact. The TTI research team will record the crash tests using highspeed digital cameras and verify that the vehicles impacted the guardrail at the MASH specified

impact speeds and angles. The TTI research team will analyze the high-speed test videos to determine the guardrail’s dynamic deflection during the crash tests and its interaction with the

fall protection device. The TTI research team will prepare a final project report after completion

of the crash testing.

REFERENCES